Sprayed urethane : a durable and ecological solution

![]()

Urethane pulverization systems

Sprayed urethane, also called polyurethane, is an environmentally friendly product. Around 15 minutes after its projection, the substance becomes solid, odorless, free of volatile organic elements, solvants or irritating fibers.

Furthermore, it is free of chlorofluorocarbons (CFC) and hydrofluorocarbons (HCFC).

The sprayed polyurethane is fabricated directly at the jobsite. The integrated pulverization system automatically doses and mixes the two components (polyol and isocyanate).

A 40 to 90 meter hose routes the pressurized products and maintains them at a constant temperature from the mobile unit to the projection site. Attached at the end of the tube is a spray gun, who will mix the components inside its mixing chamber, creating urethane.

Get a quote

Our quote requests are free. Let us convince you that we are the right team for you to carry out your insulation work.

Insulation problems?

We are best placed to meet your needs.

SUCCESS, TOGETHER

Why choose urethane?

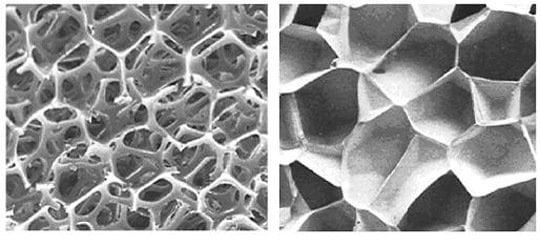

Thanks to its more compact structure, closed cell sprayed urethane offers a superior density structure. This material isn’t only waterproof, but also acts as a vapor barrier and is an excellent material against air infiltrations, making spray foam insulation very efficient.

Urethane for basements

The basement is often a risky area : high moisture level, floodings, molds…

Installing urethane under the slab and on the foundation walls spares some time and materials while providing a durable insulation and sealing of superior quality, at a very competitive cost.

Urethane to prevent RADON gas infiltration

Applying urethane under the slab ensures a perfectly-sealed jointless job, with properties preventing underground gas infiltrations like radon.

Urethane for roofs

Using spray foam insulation in the roofing is a wise solution : thanks to urethane’s impressive thermal resistance, we need less of it to obtain optimal energy savings results.